what are the three basic areas of a machine that require safeguarding

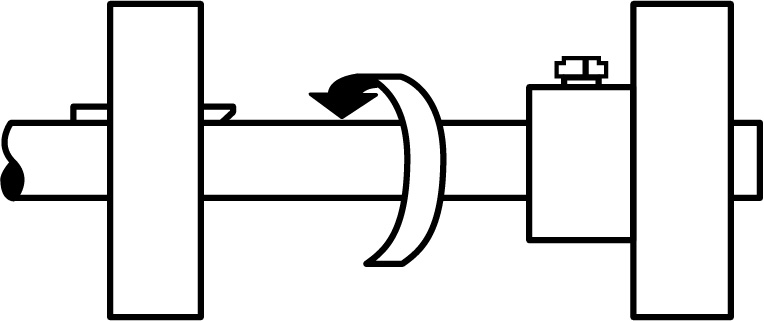

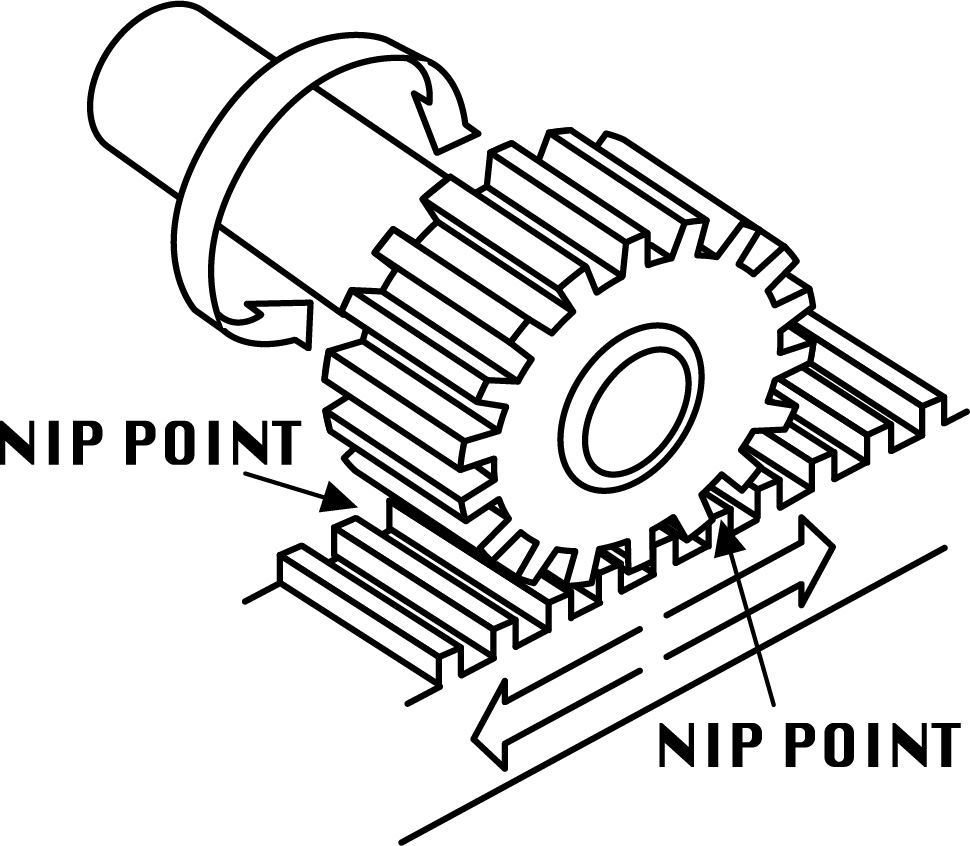

In running nip points 3. Three basic area require machine safeguarding.

Machine Safeguarding By Location And Distance

The point of operation.

. Safeguards must meet these minimum general requirements. Train personnel to know that hazard and follow the safe job method to avoid. The three areas of a machine that require safeguarding are the point of operation power transmission apparatus.

Dangerous moving parts in three basic areas require machine safeguarding. Point of operation 2. The point of operation.

The point of operation. What are the three basic areas of a machine that require safeguarding. The point of operation the power transmission device and the operating controls.

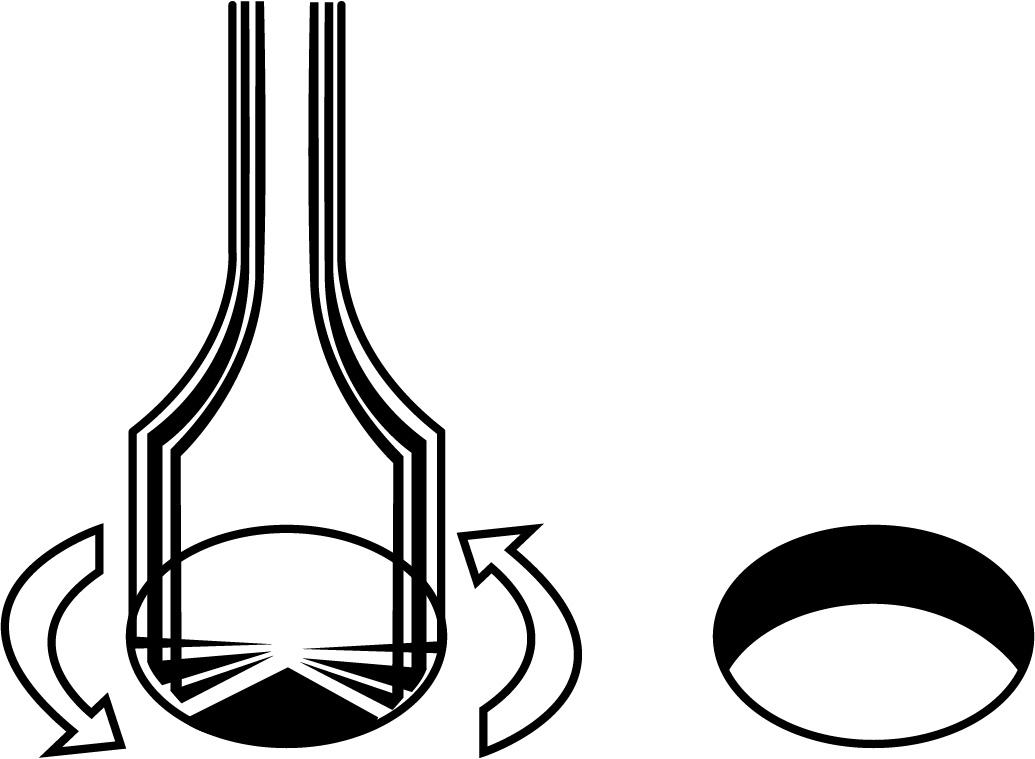

The point where work is performed on the material such as cutting shaping boring. Any machine part function or process which may cause injury must be safeguarded. The safeguard must prevent hands arms and any other part of a operators.

Point of Operation Power Transmission Apparatus Other Moving Parts Question 2. The point of operation that point where work is. The point of operation.

Friday May 6 2022. That point where work is performed on the material such as cutting shaping boring or forming of. The point of operation.

The basic steps to prevent accidents are- Eliminate the hazard from the machine method material structure etc. Dangerous moving parts in three basic areas require safeguarding. The area on a machine where work is actually performed on the material being processed eg.

Mechanical hazards typically involve dangerous moving parts in the following three basic areas. What are the three basic areas of a machine that require safeguarding. Dangerous moving parts in three basic areas require safeguarding.

What are the four basic principles of machine safeguarding. When the operation of a machine or accidental contact with it can injure the operator or others in the. That point where work is performed on the material such as cutting shaping boring or forming of.

Dangerous moving parts in three basic areas require safeguarding. Dangerous moving parts in three basic areas require safeguarding. Machine Guarding Introduction.

What are the three areas of a machine that require safeguarding. Dangerous moving parts in these basic areas require safeguarding. All machines consist of three fundamental areas.

That point where work is performed on the material such as cutting shaping boring or forming of. The point of operation. All components of the mechanical system which transmit energy to the.

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Machine Guarding Environmental Health Safety

Risk Assessment A Practical Guide To Assessing Operational Risk Ppt Video Online Download

Guards Methods Of Machine Guarding

Osha 10 Hour Machine Guarding Presentation 4

Machine Guarding Environmental Health Safety

Osha Requirements Machine Guarding Grainger Knowhow

Chapter 1 Basics Of Machine Safeguarding

Six Types Of Machine Safeguard Devices

Oshacademy Course 154 Machine Safeguarding Basic Module 1

Machine Safeguarding Seminars Rockford Systems Llc

Templates Machine Safeguarding Program

Osha Requirements Machine Guarding Grainger Knowhow

Osha Requirements Machine Guarding Grainger Knowhow

Oshacademy Course 154 Machine Safeguarding Basic Module 1